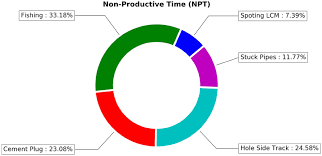

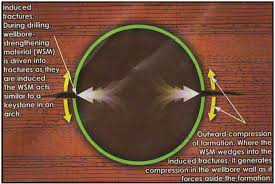

Non-productive time (NPT) is a major cost driver in drilling operations, often caused by fluid-related issues such as wellbore instability, formation damage, or equipment failure. Fluidsteq Services minimizes NPT through integrated fluid design, monitoring, and on-site support, ensuring smooth, uninterrupted operations.

Integrated Fluid Management

Fluidsteq combines lab-tested fluid formulations with field-ready adjustments, ensuring:

- Optimal density, viscosity, and chemical stability

- Protection for equipment and formation

- Continuous adaptation to changing well conditions

Data-Driven Monitoring

Through field surveys and real-time monitoring, our engineers detect anomalies early, allowing proactive intervention before NPT occurs. This data-driven approach reduces operational delays and prevents costly mistakes.

Operational Impact

Operators leveraging Fluidsteq’s solutions benefit from:

- Reduced downtime and operational disruptions

- Enhanced efficiency and safety

- Lower costs and higher project profitability

Fluidsteq Services — Engineering Fluids to Keep Your Drilling Operations Moving.