Contaminants in drilling fluids, including solids, iron particles, and other impurities, can compromise wellbore stability, damage equipment, and increase downtime. Fluidsteq Services provides high-performance filtration solutions that ensure fluids remain clean, consistent, and effective.

Precision Filtration Technology

Our filtration systems are engineered to:

- Remove suspended solids and contaminants

- Maintain consistent density and viscosity

- Protect critical pumps, tubing, and downhole equipment

Operational Advantages

Clean, well-managed fluids translate into tangible operational benefits:

- Equipment Protection – Reduced wear, longer life, and fewer breakdowns

- Fluid Performance Consistency – Maintains optimal drilling conditions for safer, more predictable operations

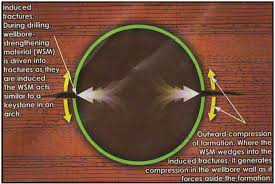

- Operational Safety – Minimizes risks associated with formation damage and drilling complications

The Fluidsteq Advantage

By integrating precision filtration with expert fluid engineering, Fluidsteq ensures operators can drill smarter, safer, and more efficiently, even in challenging formations.

Fluidsteq Services — Cleaner Fluids, Safer Wells, Smarter Drilling.